Have you ever thought about how food from the farm ends up on your plate? Interestingly, food products move systematically in a domino-like cascade from the farmers to consumers. The food supply chain encompasses all activities involved in transforming raw foodstuffs (i.e. fresh produce) into consumer-ready food products – from farming to processing, storage, distribution, and sale (Bukeviciut et al., 2009). At the same time, consumers buy food products in the supermarkets and the money paid goes to people who work at these various stages along the food supply chain, again in a domino‐like cascade from the consumer on the way back to the farmers. Hence, these two-sided pushes and pulls keep the food supply chain moving. Let’s learn the basics of the food supply chain, taking fresh apple fruits as an example and looking at how they would end up as clean apples sold in the supermarkets’ shelves or apple-based products like an apple puree.

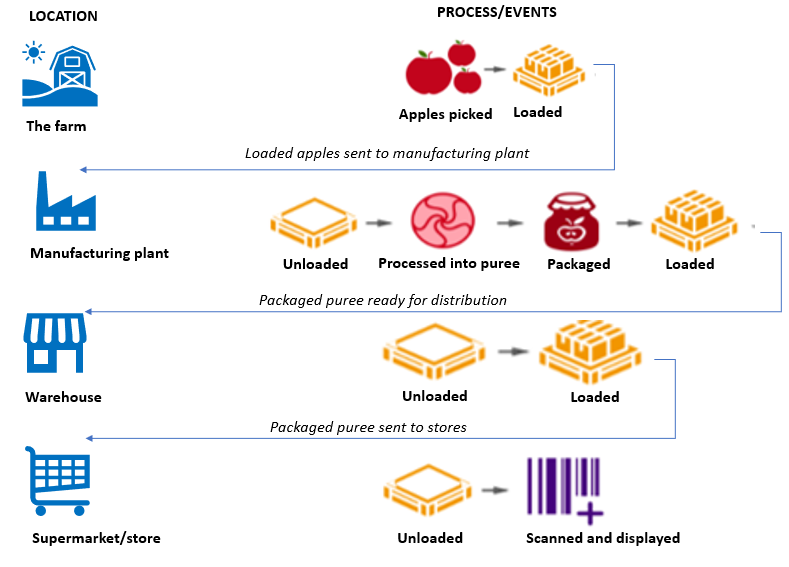

Food products undergo different steps (Figure 1) until they reach the supermarket shelf. The role of the farmer at this early stage is key; it can be considered as the engine that will drive the food chain by providing the resources (i.e. apple fruits). Once the tree has produced enough fruits which are adequately ripe to be picked, they are harvested manually or with sophisticated mechanical equipment by agriculturists, and are transported to the manufacturing plant. The transportation and storage before fruit processing is often carried out in refrigerated and specific humidity conditions to control the ripening process and avoid quality losses (Iordăchescu et al., 2019). It is worth mentioning that not all the fruits present in the apple tree will reach the manufacturing plant. Those fruits that are spoiled are already discarded at this stage.

Figure 1. Example of a complete food supply chain. “From fresh apples to apple puree in a Supermarket” (Karthikeyan, 2018).

In the manufacturing plant, the apples will be transformed into food products such as juice, puree or concentrates. This ‘transformation’ involves several consecutive steps, beginning with the selection and removal of those apples that are spoiled or do not meet the quality requirements (e.g. shape, colour). The following steps in the manufacturing process may vary depending on the final product. For example, for apple puree, after being washed the apple fruits are crushed while a short heating step is applied for enzyme inactivation and subsequently stems, peel and seeds are removed using a sieve. To ensure the safety of the final product before filling, in other words, to inactivate pathogens and extend its shelf life, a heating step is performed in the puree. This step is also known as pasteurisation and it is, together with sterilisation, applied in several other processed food products. Once the apple puree has been thermally treated, it is filled into packaging material and is stored in a warehouse (Janotová et al., 2011).

What happens next? The resulting apple puree can be sold as such or be added as a food ingredient into different products such as dairy products (yoghurts), bakery (cakes, pastry), sauces and beverages (Figure 2). Hence, when the retailers want to produce such products, the stored apple puree is transported into the second manufacturing plant where it will be subsequently added, mixed with other ingredients and transformed into the products.

Figure 2. Examples of apple-based processed products (apples used in a red cabbage preparation, apple juice and apple puree) available in a supermarket in Germany (Note: Images were captured by the authors).

After the journey of the food product/ingredient across the previous stages of the food chain, it is now ready to reach the retailers’ shelves and subsequently, the consumers’ plates! The distribution represents the term for the range of activities (transportation, handling, warehousing, packaging, etc.) involved in the movement of goods from the very beginning (point of production) to the point of consumption (Bukeviciut et al., 2009). For example, cleaned apples are taken to another packaging facility where they go through a final visual inspection. Each apple gets tagged with a sticker and then packed in boxes. Boxes are carried to the refrigerated shipping room to await exposition on the shelf to the store shelves. Similarly, for apple-based processed products such as apple puree, proper storage and handling of processed and packaged food products is very important. Usually, the products are stored in clean, temperature-controlled and dry warehouse facilities (even at refrigerated temperatures if needed) to keep them safe, traceable and of good quality (Watkins, 2016). The products are also tagged with their best before or expiration dates. When they are ready to go to market, the boxed apples or the packaged apple purees are sent to a distributor who manages the logistics to various retailers (i.e. supermarkets). The products can be transported, either by sea (ship) and/or land (delivery trucks) travel, following good practices such as maintaining proper temperature and humidity (and ethylene levels for fresh fruits). Finally, we, as consumers, find these products on the supermarkets’ shelves, with barcodes for their prices, and displayed at proper temperature and lighting conditions to maintain quality and safety for consumption.

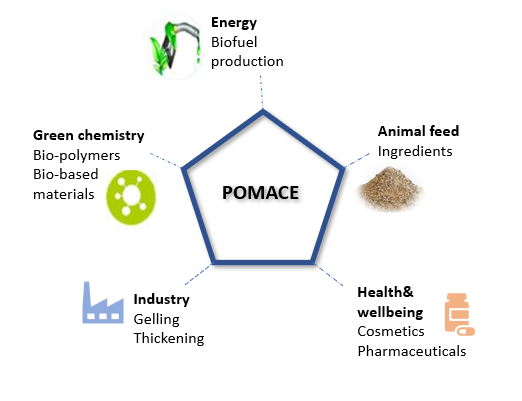

But that is not all! Often the production process leads to the generation of a huge volume of industrial waste. Is it a problem or an opportunity? The waste can be valorised by transforming it into secondary raw materials or functional ingredients. For instance, the waste obtained from the fruit and vegetable production process (leftover flesh, seeds and peel) is called ‘pomace’ and is a utilised industry by-product due to its availability in huge volumes with no/low cost (Figure 3). Currently, the apple industry utilises the pomace to produce pectin, a natural gelling or thickening agent in the food and cosmetic industry and as feed for livestock. These two applications are most popular due to the low cost of processing. The apple peel contains high amounts of bioactive compounds which are known for their antioxidative, antimicrobial and anti-inflammatory properties prompting food manufacturers to incorporate pomace in bakery based products (Débora A Campos, 2020).

Figure 3. The applications of by-products from apple pomace (The figure was created by the authors and is based on the work of Débora A. Campos, 2020).

Despite the current uses, still a lot of progress can be made to utilise the pomace better beyond the current applications in the food and health sector. The bioactive compounds can be extracted and used as natural ingredients in the pharmaceutical and cosmetic industry. Biofuels can also be produced utilising bacterial fermentation. Green and sustainable technologies (green chemistry) can be potentially applied to reduce the environmental impact. This concept which utilises industrial waste to generate high-added-value products is termed as circular economy, allowing economic benefits from waste (João C.M.Barreira, 2019). With innovation and research, the day is not far where one can witness some unconventional products from food waste- think of a coffee cup from coffee hush waste or vegan leather from apple skin.

In a nutshell, before a food product gets to the supermarket shelf, many steps are taken: production of raw materials, transformation into processed products and packaging and distribution. Moreover, the resulting waste and by-products that originated from the process can be valorised as much as possible to contribute to the circular economy. Each step of the process requires resources and is necessary to keep the supply chain moving.

-Natalia Teribia (Döhler GmbH), Sharmaine Atencio (KU Leuven) and Shruti Aravindakshan (KU Leuven)

References

- Bukeviciut, L., Dierx, A., Ilzkovits, F. (2009). The functioning of the food supply chain and its effect on food prices in the European Union. https://doi.org/10.2765/43477. Available online: https://ec.europa.eu/economy_finance/publications/pages/publication15234_en.pdf. Accessed 1 December 2020.

- Débora A. Campos, R. G.-G.-B. (2020). Management of Fruit Industrial By-Products—A Case Study on Circular Economy Approach. Molecules, 25, 320.

- Iordăchescu, G., Ploscutanu, G., Pricop, E.M, Bastón, O., Barna, O. (2019). Postharvest losses in transportation and storage for fresh fruits and vegetables sector. Journal of International Scientific Publications, 7, 244-251.

- Janotová L, Čížková H, Pivoňka, J, Voldřich, M. (2011). Effect of processing of apple puree on patulin content. Food Control, 22, 977-981.

- João C. M. Barreira, A. A. (2019). Bioactive and functional compounds in apple pomace from juice and cider manufacturing: Potential use in dermal formulations. Trends in Food Science & Technology, 90, 76-87.

- (15th of October 2018). ByteAlly Software Solutions Pvt Ltd. Available online: https://byteally.com/insights/supply-chain/integrating-with-ibm-food-trust-blockchain-guide/. Accessed 1 April 2021

- Watkins, C. B. (2016). Transport of Fresh Produce. In Encyclopedia of Applied Plant Sciences (Second Edition, Vol. 1). Elsevier. https://doi.org/10.1016/B978-0-12-394807-6.00218-5.

An integrated food quality research and training programme

An integrated food quality research and training programme